Arianna – IA

It is one of the most known and appreciated companies in the field of robotics and automation. It has been active in the sector for more than 35 years, proposing continuous innovations and improvements. Thanks to this experience we are able to always respond effectively to all the various needs of the manufacturing industry. The presence of a team of highly specialized technicians allows continuous evolution. The work with passion and commitment in the construction of robotic lines provides customers with reliable solutions, able to:

- save time;

- making procedures more efficient;

- earn more;

- improving people’s working conditions.

Website: autind.com

-

300+

customers worldwide

-

24

countries

-

1,383

installed robots

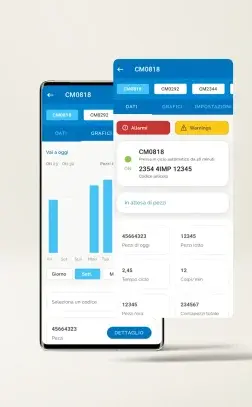

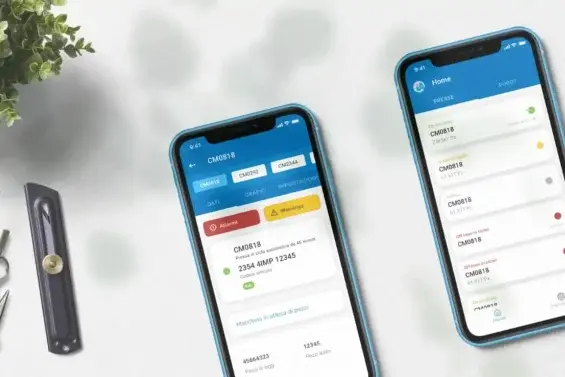

The Arianna – IA App offers Automazioni Industriali's customers a quick and accurate tool to remotely monitor both the machine status and its key information in a few simple steps.

First of all, thanks to this Application it is possible to obtain, in real time, the machine status (run / stop) by checking how many minutes it has been in a certain state. In addition, it is possible to view production-related information, such as the number of pieces produced during the day. There's also the possibility to access a detailed list of alarms and warnings without any direct intervention on the machine. In the graph section, on the other hand, it is possible to monitor the production on a daily, weekly, monthly or annual basis.

By accessing the 'detail' section, you can view the number of pieces produced for each individual article in the different time intervals.

Last but not least the App provides the user with the option of configuring a series of notifications in order to stay up-to-date on any changes in status.

Initially the company was using the internal development of a first version of the manufacturing software. The difficulties encountered required relying on DuckMa and its innovative capabilities to develop a mobile app. The need was to publish the app on Google and iOS stores, to easily distribute it to all its customers. The app had the purpose to manage automation systems and electric presses. The problem arises in particular from the extent of the territory in which the affiliated companies are located, which in its entirety cover 23 countries in the manufacturing industry.

Finally, it was expanded to allow effective after-sales service and a training program for in-house engineers, who then took over the management. A great opportunity for the manufacturing industry.

App Collected Results.

About 2 months after its publication (November 2021), we have gathered the first positive feedback from entrepreneurs, production managers, machine operators who use the application and find it useful and intuitive.

Currently, the company has decided to push the distribution of the Mobile App in the Italian and English language version to electric press customers.

The market reaction has been very positive to the extent that some users are now requesting new functions, which is evidence of the strong market acceptance.

The Application will, in the near future, be used by the sales force as a value-added solution of an Industrial Automation system or press.

Let's create your Success

Project together!